- Welcome to China Calcium Carbonate Manufacturer

- WeChat:15078781000

Coated Calcium Carbonate Powder Supplier from China

- Category: Calcium Carbonate

- |

- Date: 2025-06-09 10:47

Surface-treated coated calcium carbonate powder with stearic acid for improved dispersion, hydrophobicity, and polymer compatibility in plastics and rubber.

Product Details

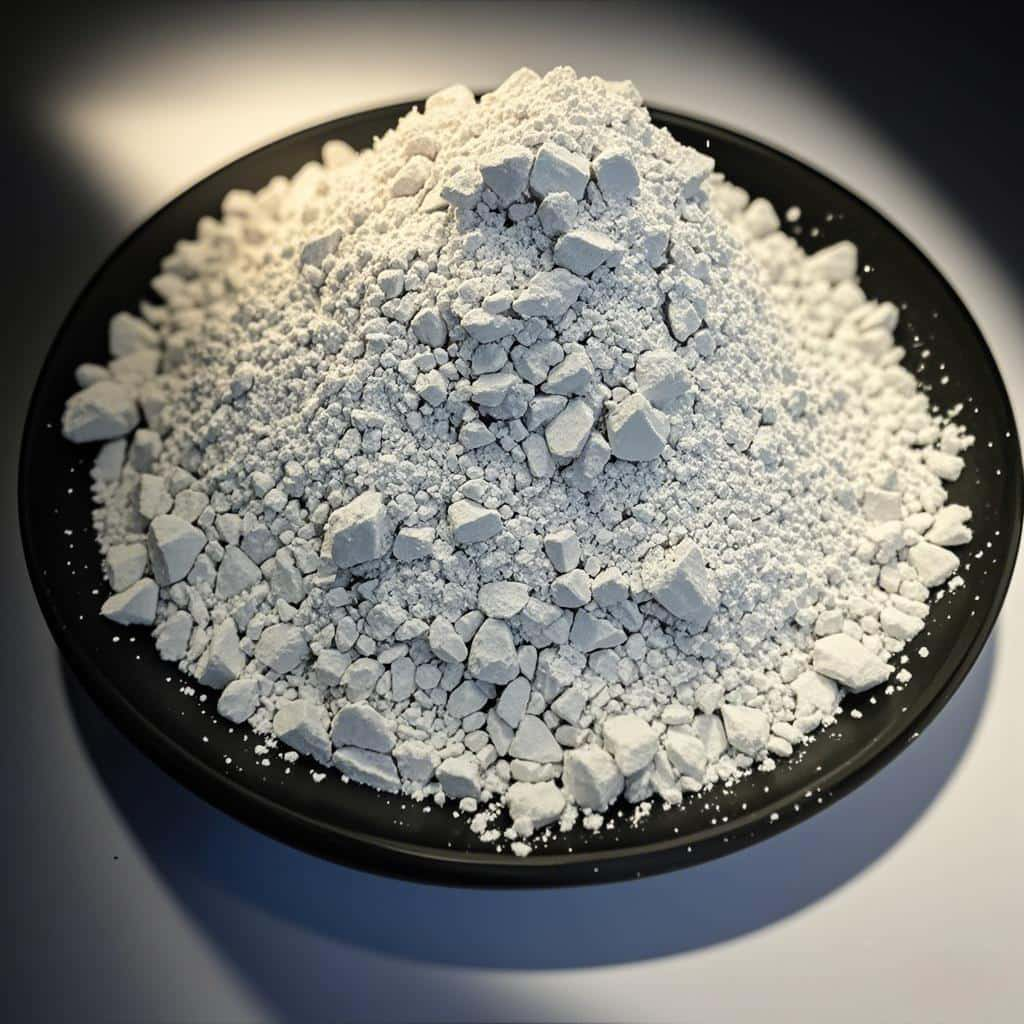

Image ALT Suggestion: High-purity stearic acid coated calcium carbonate powder for plastics and rubber applications

Coated Calcium Carbonate (CaCO₃) is a surface-treated version of calcium carbonate that enhances dispersion, compatibility, and performance in polymers, coatings, rubber, and more. We manufacture and export high-purity coated CaCO₃ powders treated with stearic acid and other modifiers to meet industry-specific needs.

🏢 What Is Coated Calcium Carbonate?

Coated calcium carbonate is ground or precipitated CaCO₃ with a surface layer of organic coating agents such as stearic acid or polymer surfactants. The coating enhances hydrophobicity, improves matrix compatibility, and supports better processing.

CAS No.: 471-34-1

HS Code: 28365000

Other Names: Stearic acid coated calcium carbonate, coated GCC, coated PCC

🔪 Key Specifications

| Parameter | Typical Value |

|---|---|

| Appearance | White fine powder |

| Coating Agent | Stearic acid (or custom options) |

| CaCO₃ Purity | ≥ 98.5% |

| Particle Size (D50) | 1–10 μm (customizable) |

| Coating Rate | 1.0% – 2.5% |

| Moisture | ≤ 0.3% |

| Oil Absorption | 15–25 g/100g |

| Bulk Density | 0.9–1.2 g/cm³ |

📚Difference Between Coated and Uncoated Calcium Carbonate

| Feature | Coated CaCO₃ | Uncoated CaCO₃ |

| Surface Treatment | Yes (e.g. stearic acid) | None |

| Hydrophobicity | High | Low |

| Polymer Compatibility | Excellent | Moderate |

| Dispersion | Superior | Average |

| Typical Use | Plastics, rubber, masterbatch | Paints, paper, cement |

Learn more: What is the Difference Between GCC and PCC Calcium Carbonate?

🔧 How to Make Coated Calcium Carbonate?

Coated calcium carbonate is typically produced by:

Grinding high-purity limestone (for GCC) or precipitating (for PCC).

Applying a coating agent such as stearic acid in a controlled mixer.

Controlling temperature and rotation speed for optimal surface modification.

Quality testing for coating uniformity, particle size, and performance.

Our facility uses advanced surface treatment lines with real-time QC.

📊 Coated Calcium Carbonate Powder Uses

Plastics (PVC, PE, PP): Enhances strength, surface finish, and processing speed.

Rubber Compounds: Improves abrasion resistance and tensile properties.

Masterbatch: Excellent dispersion and flow behavior.

Paints & Coatings: Enhances scrub resistance and gloss.

Paper Industry: Optional use for paper filling and coating.

Others: Adhesives, sealants, cables, cosmetics.

📅 Coated Calcium Carbonate Price & Supply

- Pricing depends on:

- Particle size & coating rate

- Type of CaCO₃ (GCC vs PCC)

- Quantity (tons per order)

- Packaging format

Contact us to get your best FOB/CIF price. We offer:

- OEM / ODM specs

- Free samples for lab testing

- SGS / REACH / RoHS documentation

- 25kg bags / 500kg jumbo bags / custom packaging

🌐 Why Choose Us as Your China Manufacturer?

Over 15 years of experience in CaCO₃ processing

ISO 9001-certified factory with international clients

Strong customization capability (particle size, coating, branding)

Technical support team for industry applications

✉️ Visit our Homepage to explore full product range

📖 FAQ

Q: What is the CAS number for coated calcium carbonate?

A: CAS No. is 471-34-1 (same as uncoated calcium carbonate).

Q: What coating agents are commonly used?

A: Stearic acid is most common. Others include silanes, titanates, and polymer dispersants.

Q: Can I get MSDS for coated calcium carbonate?

A: Yes, full MSDS available upon request.

Q: What’s the difference between coated ground calcium carbonate and coated PCC?

A: GCC is mechanically ground; PCC is chemically precipitated. Both can be surface treated.

Q: Do you export globally?

A: Yes, we ship to 40+ countries across Asia, Europe, the Americas, and Africa.

✉️ Contact Us for Best Price or Free Sample

We supply coated calcium carbonate for plastics, rubber, coatings, and more. Request your quote, MSDS, or technical data sheet today.

✉️ Email: addy34152@gmail.com

🌐 Contact Page: Click Here